Lifex experts work with each customer to design a tailor-made solution to their specific shipping challenges – and our training centers offer every Lifex customer the opportunity to participate in our Cargo Securing Training program.

Book an appointment with your Lifex engineerShip Securing

Ship Securing

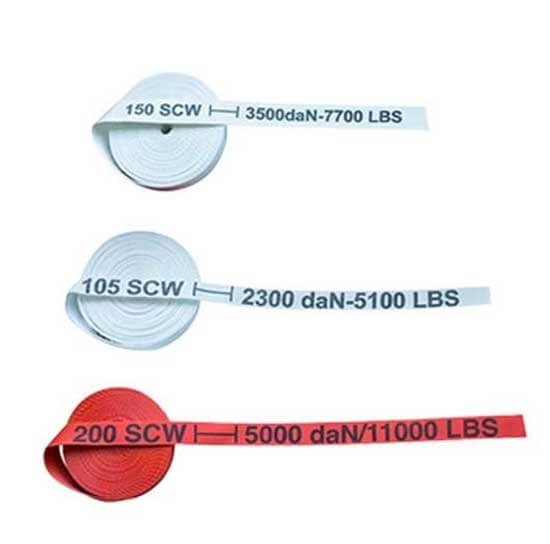

Ship securing with composite strapping involves using a strong and durable material made from a combination of polyester fibers a9nd adhesive to secure cargo on ships. This method of securing cargo offers several benefits over traditional methods like steel strapping or wire rope.

One of the main benefits of using composite strapping for ship securing is its high tensile strength. Composite strapping can handle heavy loads and withstand the rigors of sea travel without breaking or snapping. Additionally, composite strapping is flexible and can easily conform to the shape of the cargo being secured, providing a snug and secure fit.

Another advantage of composite strapping is its resistance to weathering and corrosion. Unlike steel strapping, which can rust in a marine environment, composite strapping is not affected by moisture, saltwater, or UV rays. This makes it a reliable option for securing cargo on ships that may face harsh environmental conditions during transit.

Additionally, composite strapping is lightweight and easy to handle, reducing the risk of injury for workers involved in the securing process. It also does not have sharp edges like steel strapping, making it safer to work with and reducing the risk of damage to the cargo.

Overall, ship securing with composite strapping is a reliable and cost-effective method that offers superior strength, flexibility, and durability compared to traditional securing methods. By using composite strapping, ship operators can ensure that their cargo arrives safely and securely at its destination.

Benefits

Increased Safety

Composite strapping is designed to securely hold loads in place during transportation, reducing the risk of shifting or falling.

Durability

Composite strapping is made from high-strength materials such as polyester fibers and polypropylene, which are resistant to tearing and breaking under pressure.

Cost-effective

Composite strapping is a more affordable alternative to steel strapping, providing the same level of performance and reliability at a lower cost.

Lightweight

Composite strapping is much lighter than steel strapping, making it easier to handle and transport while still providing strong and secure support.

Weather Resistance

Composite strapping is resistant to UV rays, moisture, and extreme temperatures, making it suitable for outdoor and long-distance transportation.

Easy To Use

Composite strapping can be easily applied and tensioned using manual or pneumatic tools, offering a quick and efficient solution for securing shipments.

Environmentally Friendly

Composite strapping is recyclable and can be disposed of responsibly, reducing the environmental impact of packaging materials.