Fibers, Chemicals

Fibers, Chemicals

In the fibers and chemicals sector, the need for durable, reliable, and efficient packaging solutions is paramount. Composite strapping has emerged as a preferred choice for securing and bundling various products ranging from raw materials to finished goods. This page explores the benefits, applications, and specifications of composite strapping, highlighting its significance in enhancing operational efficiency and product safety.

What is Composite Strapping?

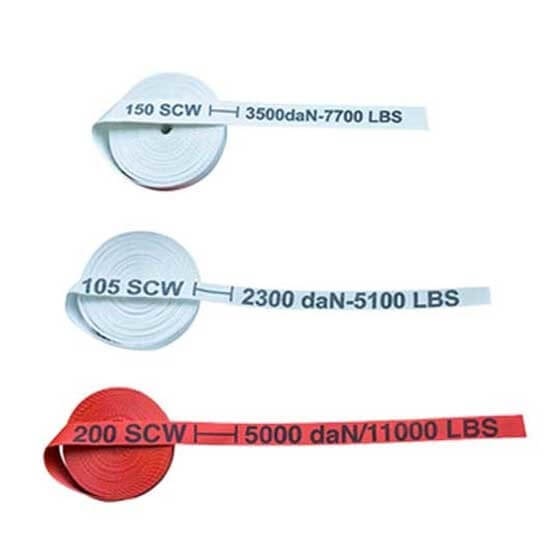

Composite strapping is a type of packaging material that combines the strength of plastic and the reliability of steel in a lightweight, flexible form. It typically consists of a core made from high-strength polyester or polypropylene, reinforced with steel filaments or other robust materials. This unique composition provides the benefits of traditional steel strapping without the associated drawbacks, such as weight and potential injury risks.

Key Benefits

- Superior Strength and Durability: Composite strapping offers a high tensile strength, making it ideal for heavy loads and providing excellent resistance to breakage during transport.

- Lightweight and Flexible: Unlike steel strapping, composite strapping is lightweight, which reduces shipping costs while still providing robust support. Its flexibility allows for easier handling and application.

- Corrosion Resistance: The materials used in composite strapping are typically resistant to corrosion, making them suitable for the chemicals sector where exposure to harsh environments and substances is common.

- Safety: Composite strapping eliminates the risk of sharp edges associated with steel strapping, reducing the likelihood of injuries to workers during application and removal.

- Environmental Considerations: Many composite strapping products are recyclable and can be produced using sustainable practices, making them an eco-friendly choice for companies looking to reduce their carbon footprint.

Application

Composite strapping is versatile and can be used in various applications within the fibers and chemicals industry, including:

- Bundling Raw Materials: Ideal for securing bales of fibers, chemicals, and other bulk materials for transport.

- Unitizing Pallets: Ensures that multiple items stay securely together during shipping and handling.

- Securing Finished Products: Protects products from damage during transit and handling, ensuring they arrive in optimal condition.

- Stabilizing Loads: Helps maintain load integrity, preventing shifting that could lead to product loss or damage.

For expert advice on industrial solutions contact us now

CONTACT FORM

Enter your details in the form and we will call you.

Our Global Quality Commitments